Ship Building

By Arthur Woodgate

It’s been rather nice thinking about Rye Shipyard since that loving presentation in the Autumn issue of ‘Ryes Own’, and it’s given me a lot to think about. We know that Sussex was covered at one time by a lot of forestry, and there must have been lots of it’s timber cut down and brought into Rye Shipyard.

A one time famous firm of Rye, Wright and Pankhurst; had the right equipment and men to cut down the Sussex oak and bring it into Rye Shipyard and I would think mostly from the Beckley Area. Mr Pankhurst of the firm Wright and Pankhurst was a gruff sort of man, but very considerate for the welfare of his men and lovely shire horses that brought in the oak. He would go and look at the site of his contract and judge if his men and horses would be able to carry out the works in a safe manner, and if it would not be too difficult for his horses to pull out the tree trunks. Having given the ‘O.K’ his Rye men would ‘out’ axes and saws.

I never saw his timber tugs being loaded but it had to be a very difficult job with plenty of ropes. Good job we had a ‘rope walk’. I did once see a tug coming through the streets with tree trunks on it with two horses. What a lovely sight. There were some smaller timber carriers about and they supplied the boat builders who would have seen to the punts and lifeboats.

I got to know the sawyers fairly well – top sawyer Mr Harris and bottom sawyer Mr Penfold. The builder’s yard where I spent some time in, and the sawpit, had only the Sloane. This was a waterway too small to call a river but too big to be a drainage ditch. I had a chance to get across or around it at break time and was able to talk to the sawyers. I used to see Mr. Harris in the street, but the man in the bottom of the pit got rather dusty and he would not want to get too close.

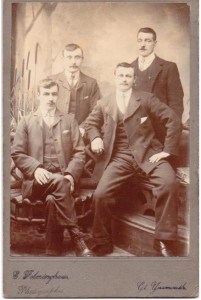

My Uncle, Frank Batcheler is standing at the back on the left in this amazing old photograph that came from an album given to Arthur’s mother in 1907 when she was nineteen. Frank Batcheler would have been in his mid twenties. I often would wonder what his wife thought of it all.

Moving on now the beams and boards would be placed onto the bending machine, just inside the works proper. There was an independent little shop where the turner worked. Mr. Ted Phipps and my father knew each other very well and Mr. Phipps was allowed to do some turning. Now as a stone mason my father used to need a new bell-shaped mallet from time to time, so father had to find some solid holly and keep it to dry out, then get it turned. I would help dad to look out a holly trunk, then see the farmer to let us cut out the holly from the hedge and take it to Ted.

In the Beckley woods there was also a furnace where the small pieces of metal including the cannon was made, and later E.P.S Jones of the Rother Iron Works joined in and got their iron oar from the Beckley woods. I’m still wondering where the bodies of the steel steam fishing smacks were made. Yes we had panel beaters which could have beaten out any panels, but I don’t know where they could have been put together to form ships bodies. There seems no place where this could have been done, but thinking as I write it came to my mind that as there was a slipway from the Rother Iron Works straight into the River Rother, that they could have put an iron ship side together in the works and get it to the River down their shipway, which as far as I know was only used for pulling up boats for repair and re-launching them there. Now that would have bought Rye ship’s ship building industry the length rock channel, from the Brede to the Rother, so from the Acorn to the Anvil, think about it.

As the industry began to slow down redundancies began to affect the labour force and some men began to drift into our landlubbers site and we seemed to absorb them, including Bob Burgess who stayed with us then as a carpenter. I knew Percy Jempson who started a building business centred in Peasmarsh. I’ve been fascinated with the shipyard after my August copy of “Ryes Own” was delivered.

The name Goodsell rings a bell and I’m sure one of that name married into my family and the name of Finnis was familiar and I’m sure I knew of him and even met him. What big and heavy tools shipwrights had against the carpenter. Bob Burgess had a screwdriver as big if not bigger than George Finnis’s spanner. Whilst all of this was going on, an uncle of mine Frank Batcheler was working at the yard. He was not happy with the wages and decided to try and get it put right. They had recently finished three ships which had been launched – Surprise, Sunrise and Enterprise.

Uncle tried to get a campaign so he had some posters worded ‘Sunrise Surprise and Enterprise men’s’ wages never rise’; and got them shown around the town. That was the end of his time building ships in Rye. He went to Chatham where he still felt the same but he had no trouble about work. He was employed in Chatham Dockyard, married a Chatham lady, had a family of two daughters and two sons, and lived what seemed a happy married life for quite a few years but suddenly we got the message he had been found drowned in the Medway.

Launch of the “Pentire” from the Smith Yard September 1910. A photograph from the Whiteman Postcard series. A large contingent of dignitaries, townspeople and the many workers who had constructed the craft were on hand to wait for the tide and witness the launch of another Rye built vessel.

“Rye’s Own” November 2012

All articles, photographs and drawings on this web site are World Copyright Protected. No reproduction for publication without prior arrangement. © World Copyright 2015 Cinque Ports Magazines Rye Ltd., Guinea Hall Lodge Sellindge TN25 6EG